FABRIK

FABRIK or Forward And Backwards Reaching Inverse Kinematics is a simplified but very computationally efficient approach to solving inverse kinematics. When compared to CCD and Jacobian inverse kinematics, FABRIK diverges to a solution approximately 10 and 1000 times faster respectively. Instead of transformation stacking the kinematic change can be described as a simple series of joint ends connected by lines. Given the current joint angles of a robot and information about each joint length the FABRIK approach can be used to derive drive angles based on a new target location.

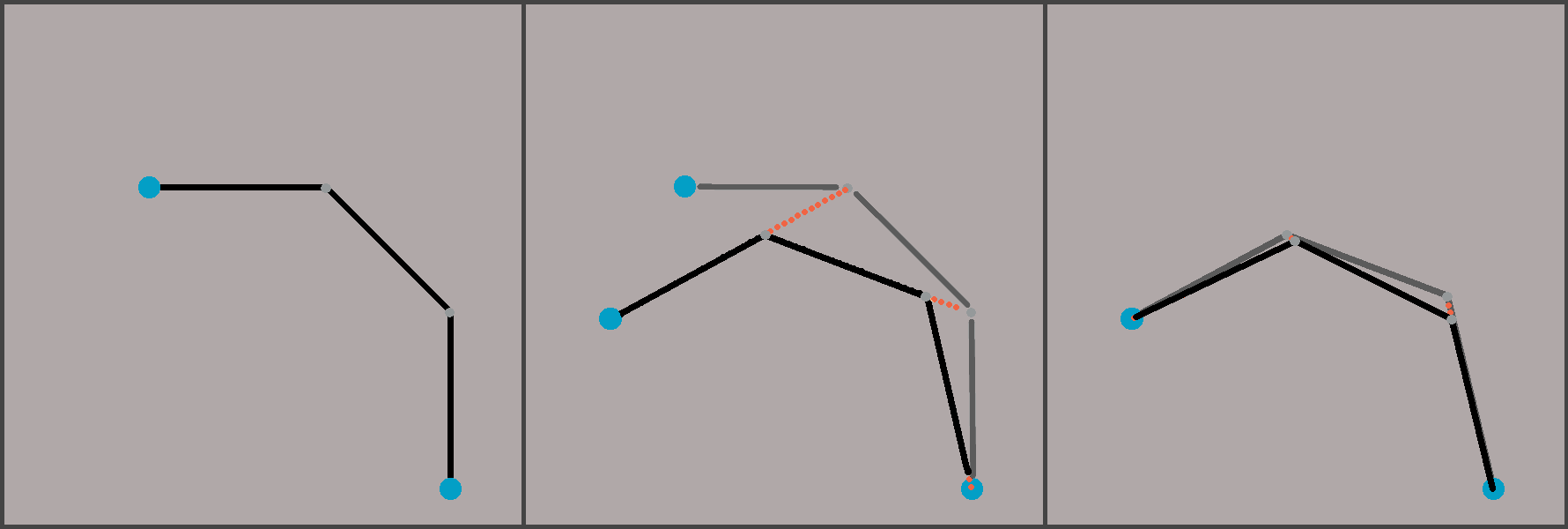

Result after one FABRIK iteration

The exposure to this technique came while researching a project I was working on for a previous employer so I unfortunately do not have any great videos to demonstrate the solution at work. Maybe I will spin up a quick project in the future. The image above illustrates one iteration of the FABRIK iterative process. When a new target is requested the fist step is to backwards project a line from the new target to the current location of the adjacent downstream kinematic joint. This line will not end on the adjacent downstream joint as the line needs to projected at the same length as the joint it represents. Thus, any new target location will require a new kinematic chain. This backwards line projection continues in this manner until the kinematic chain base is reached. Once the base is reached you reverse direction along the kinematic chain and head back to the target location. Every time you go along the chain from the new target location to the kinematic base and back to the new target location one iteration of the FABRIK approach has been completed. It can be seen in the image above that FABRIK diverges very quickly with just one iteration. An interesting part of this approach is that you never actually get the angles needed to reach the new target location, mathematically speaking that is. This is because you are always getting closer but you are never at the target location. However, within a relatively small number of iterations you are at the target location well within the resolution of the robot that is being described by the kinematic chain.

Room for Improvement:

It may be straight forward but one thing to considers is that the FABRIK kinematic chain in its simplest form is free from real world constraints. Additionally, it assumes that the axis of articulation has more than one degree of freedom which most robots do not. In order to leverage FABRIK for an industrial application you need to maintain constraints such that is does not make a move that violates the limitations of the device it is used to represent. By this I mean, the line projections must follow the actual degrees of freedom the joint it represents is constrained by. If the symmetry of the robot kinematic chain allows, you can combine two joints into one. For example, assuming you are using a robot that has joints very similar to maneuverability of a human arm the joint that creates a rotation parallels to the axis of the “Forearm” and the joint that controls the “Elbow” can be condensed to one kinematic chain.

The FABRIK approach is often characterized as diverging to a solutions that appear to be more anatomical and less robotic. It does however suffer from having a “lazy” posture at times. For example, lets go back to the robot configured like a human arm. If you start in a position with the robots elbow facing upwards and produce a dithering motion alone a plane parallel to the ground the kinematic solution will tend to bring the elbow down as it finds a local minimum. If it is desired to keep the elbow pointing upwards you have to implement some sort of weighting scheme that, unless there is no other solution, the iteration process itself will bias towards having the elbow facing upwards. Having the elbow directly in the air may be advantageous for things like obstacle avoidance as well as something simple as general presentation.

Another thing that needs to be considered is that thus far the solution has been limited to a target location. No constraints were given related to targeting a fully or mostly constrained frame which is almost always the required case. An example of a mostly constrained frame could be if you have axial symmetry that allows for an additional degree of freedom in the target frame. For example, a welding tip has a higher level of orientation freedom than picking and placing an asymmetrical part. The new target location as described in the previous portions do not take into account being constrained by the target frame only a target location. This can be resolved by removing one kinematic link from the chain as it is, if there is a solution, determined by the target frame. A new target location can be derived by backwards projecting the removed linked geometry based on the given target frame such that when the remaining links “reach” this location a valid set of drive angles have been derived. Additionally, in the case of having an end effector with axial symmetry you may get a plane of potential solutions that can be used to diverge robot drive angles.